Originating naturally from the earth, Radon is a radioactive vapor that is completely colorless and scentless. This gas creates significant health dangers, including the risk of lung cancer, when it becomes trapped and concentrates within structures or active work sites. Therefore, implementing effective radon mitigation strategies is a fundamental safety requirement for any construction project. Without proper mitigation, radon can affect not only the construction workers during the build but also the future occupants of the building. In this article, we will explore comprehensive strategies for radon gas removal, ensuring that your construction project is safe and compliant.

What is Radon and Why Is It a Concern on Construction Sites?

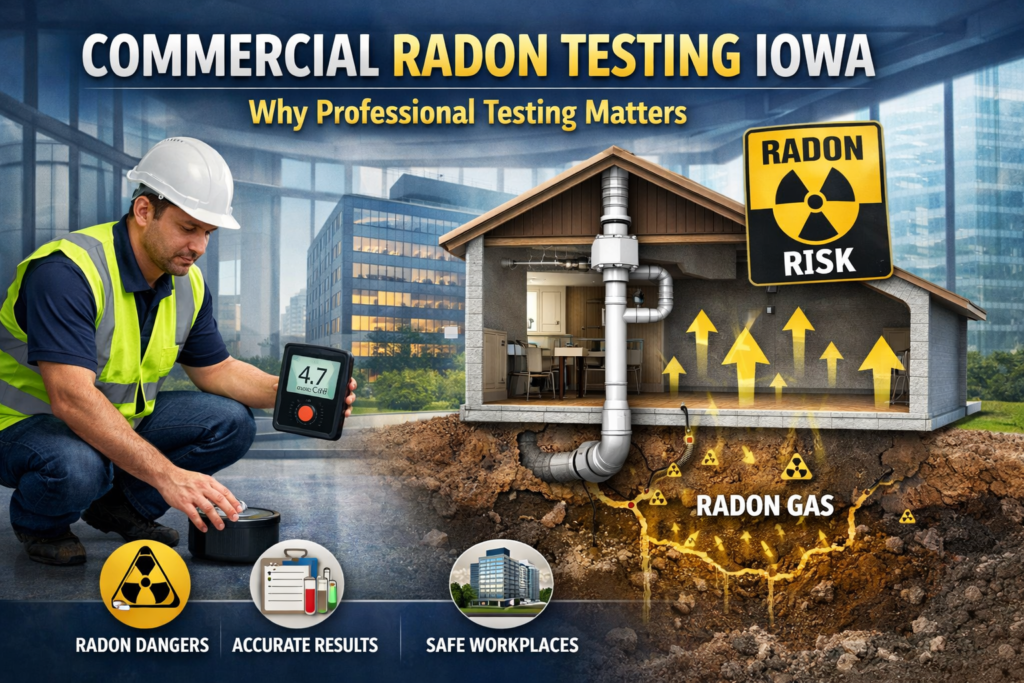

Radon is a naturally occurring gas that comes from the decay of uranium in the earth’s crust. It can enter buildings through cracks in foundations, joints, and other openings, and accumulate in poorly ventilated spaces. On construction sites, the risk is amplified because the disturbance of soil and the opening of foundations create potential pathways for radon to infiltrate. Radon is a silent and dangerous threat. Long-term exposure to elevated radon levels is the second leading cause of lung cancer in non-smokers. Therefore, managing radon during construction is not just about meeting regulations; it’s about protecting the health and safety of everyone involved and ensuring that the building remains a safe environment for its future occupants.

Why Radon Mitigation Should Be a Priority on Construction Sites

Radon gas is a serious health risk on construction sites, requiring early mitigation to protect workers and future residents while ensuring compliance.

- Radon poses serious health risks, affecting workers and future residents’ respiratory systems by eliminating it during construction.

- Many regulations mandate radon mitigation during construction, and non-compliance can lead to fines, legal issues, and costly retrofits.

- Mitigating radon early in construction is more affordable than retrofitting later, saving money and avoiding delays.

- Proper radon mitigation increases property value, offering a healthier environment that attracts potential buyers.

- Radon removal systems improve indoor air quality, reducing pollution risks and creating a healthier environment for occupants.

Addressing radon during construction saves costs, improves air quality, and boosts property value, making it an essential step for every project.

Ensuring Safe Construction: Key Radon Mitigation Strategies

Radon gas is a significant health risk on construction sites, but with proper planning and mitigation, it can be effectively managed.

1. Initial Radon Testing and Site Assessment

Before construction, conduct soil gas measurements and radon testing around the foundation area. This helps determine if radon is present and guides the need for mitigation. Early testing ensures proper planning for radon removal.

2. Plan Radon Mitigation Early

Incorporate radon-resistant design features, such as passive ventilation systems and sub-slab depressurization. Install vent pipes and seal gaps to prevent radon infiltration. A solid plan ensures effective long-term mitigation.

3. Radon Mitigation System Installation

Integrate the radon mitigation system during construction by installing vent pipes and sealing cracks. Use radon-resistant membranes under the slab to block radon from entering. Proper installation is essential for effective prevention.

4. Post-Construction Radon Testing

After construction, test the building’s indoor air to ensure the mitigation system is working. If radon levels are high, increase fan power or seal overlooked areas. This step ensures the safety and effectiveness of the system.

5. Ongoing Maintenance and Monitoring

Perform regular checks on the radon system, including fan operation and ventilation inspections. Reassess the system after any building alterations to maintain its effectiveness. Ongoing maintenance ensures continuous protection from radon.

Implementing key radon mitigation strategies during construction is essential for long-term safety and compliance. From initial testing to ongoing maintenance, these steps will ensure effective radon removal and provide peace of mind for everyone involved.

Essential Radon Mitigation Practices for Construction Projects

Radon mitigation is vital for construction projects to ensure safety and compliance. Early action helps prevent costly issues later.

i) Integrate Radon Mitigation Early: Include radon-resistant features in the initial design phase to save costs and ensure long-term efficiency.

ii) Collaborate with Radon Professionals: Work with certified radon mitigation specialists for accurate assessments, system designs, and proper installations.

iii) Document Everything: Maintain detailed records of radon testing, designs, installations, and ongoing maintenance for future inspections and liability management.

iv) Educate the Construction Team: Ensure all team members, including subcontractors, understand the importance of radon mitigation and follow the necessary procedures.

By integrating radon mitigation early, collaborating with experts, and educating the team, construction projects stay safe, efficient, and compliant. Learn more about Radon Mitigation Ankeny.

Conclusion

In conclusion, radon gas removal from construction sites is a critical step in ensuring the health and safety of everyone involved in the project. From initial testing and design to installation and ongoing maintenance, a comprehensive strategy will protect workers, future occupants, and the long-term integrity of the building. Partnering with professionals like DSM Radon ensures that radon mitigation systems are correctly designed, implemented, and maintained, providing peace of mind and compliance with safety regulations.

FAQs

Q1: What is the acceptable radon level after mitigation on a construction site?

The general target is to reduce radon levels to below 4 pCi/L, which is the EPA’s action level. However, achieving the lowest possible levels is always the goal.

Q2: Can radon mitigation be installed after construction is complete?

Yes, but retrofitting radon systems is more disruptive and expensive than installing them during construction. It’s always better to incorporate radon mitigation from the start.

Q3: How do I know if my mitigation system is working?

Radon testing after installation ensures that the system is working correctly. Periodic checks are also necessary to ensure long-term effectiveness.

Q4: How often should a radon mitigation system be inspected?

It’s recommended to inspect the system annually to ensure it is operating efficiently. Regular maintenance is key to sustaining its effectiveness.