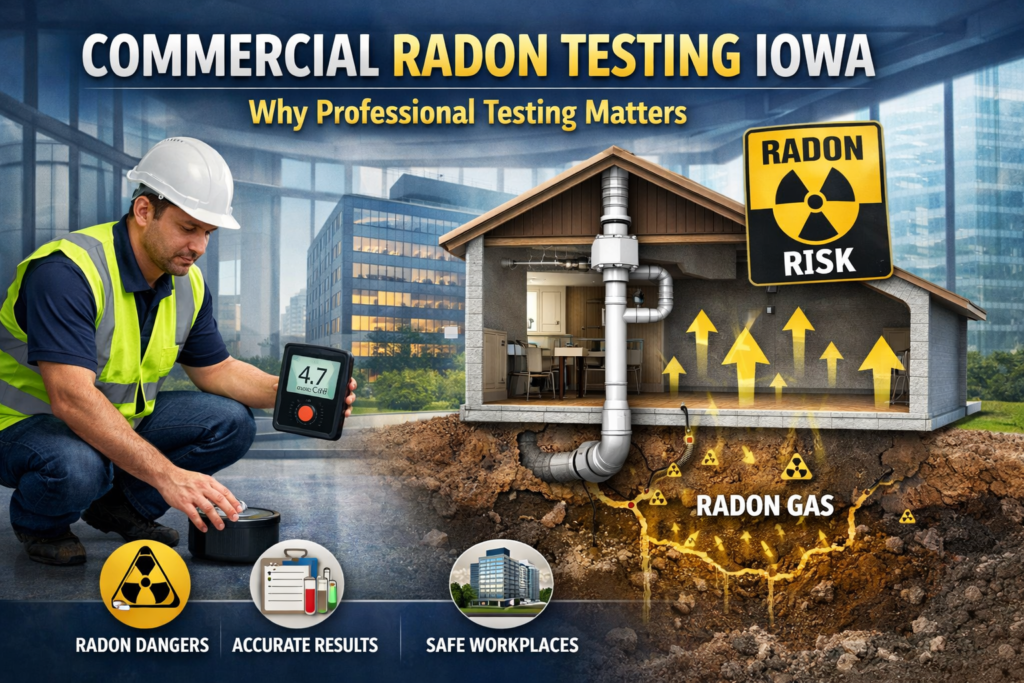

Radon rises from soil into buildings, so people often miss the risk until a test reveals it. Moreover, the Midwest includes broad areas of uranium-bearing soils, glacial deposits, and fine-grained sediments that can release radon gas over time. Consequently, Radon levels in Midwest agricultural states can rise in homes, schools, and workplaces even when a building looks solid and well-maintained. Instead of guessing, a clear testing-and-action plan creates certainty and reduces long-term exposure risk.

Why Agricultural Regions Often Show Persistent Radon Potential

Agricultural states frequently sit on wide geologic formations and glacial till, so the ground can generate radon steadily. Additionally, many rural properties rely on basements, crawlspaces, and slab edges that connect directly with soil pathways. As a result, small openings around sump lids, utility penetrations, and slab joints can become radon entry points. Meanwhile, energy-efficiency upgrades can reduce natural air exchange, which can keep radon trapped indoors longer.

Moreover, farm buildings with attached garages and utility rooms can create extra pressure changes, so radon entry patterns can intensify during daily use. This means that radon levels can fluctuate throughout the day, especially with changes in ventilation or external weather conditions. Additionally, properties with older construction may have more vulnerabilities, making testing and mitigation even more critical.

How Building Pressure Pulls Radon Indoors

Building pressure differences pull radon indoors through tiny openings. These five drivers explain why levels change and why consistent testing stays important-

- Stack Effect: Warm indoor air rises and escapes from upper levels, so the lower level pulls soil gas in to replace it.

- Exhaust Appliances: Bathroom fans, kitchen hoods, dryers, and fireplaces push air out, so the building pulls air from the easiest path—often the soil.

- HVAC Imbalance: Leaky ductwork, return-air placement, and closed interior doors can create stronger suction in basements and mechanical rooms.

- Wind Load: Wind loads one side of the structure and depressurizes the other side, so radon entry can spike even when nothing else changes.

- Soil Moisture: Heavy rain or frozen ground reduces soil air movement, so soil gas seeks alternate pathways and can push more radon through cracks and sumps.

When these pressure forces increase, radon entry rises fast. Regular testing and proper mitigation keep basements, schools, and workplaces safer year-round.

Common Entry Points in Midwest Homes, Farms, and Community Buildings

Radon enters through structural and service openings, and it uses the easiest path available. For example, these areas often deserve priority attention during inspections and mitigation planning:

- Cracks in the basement slabs and control joints

- Sump pits, drain tiles, and open crock lids

- Utility penetrations for water, gas, and electrical lines

- Floor-wall seams and block foundation voids

- Crawlspace soil surfaces and unsealed access points

Additionally, larger buildings can include multiple pressure zones, so radon can concentrate differently across wings, lower levels, and mechanical rooms.

Testing That Builds Confidence

Testing provides the only reliable evidence because radon has no smell or visible signal. Therefore, a structured test plan matters more than a quick gadget check. Many teams use short-term tests for initial screening, and they use long-term tests when they need stronger confidence across seasons.

Additionally, stable building conditions during the test window improve reliability, because open windows and unusual ventilation can distort results. Moreover, a follow-up test after any major change protects accuracy, because renovations and HVAC updates can shift airflow and pressure. Consistent testing practices help ensure that radon levels are accurately measured, providing a clearer picture of long-term exposure risks.

How to Interpret Results Without Confusion

Radon numbers only help when teams interpret them consistently. These six steps turn test results into clear actions, priorities, and documented next moves.

- Action Level: Compare the result to the action threshold, then decide whether to retest or mitigation based on that benchmark.

- Room Use: Prioritize spaces with long daily occupancy, like basements, classrooms, daycare rooms, and work areas.

- Borderline Risk: Treat near-threshold results as a signal, so schedule a follow-up test for clearer decision-making.

- Season Shifts: Expect readings to change with winter heating and weather, so confirm patterns across different seasons.

- Clear Records: Log result, test type, device location, and next step immediately, so teams avoid delays and confusion.

- Proof Test: Complete a post-mitigation verification test, because measured results confirm the deduction and prevent false confidence.

Clear interpretation prevents delays and wrong assumptions. When teams document decisions and verify mitigation, they protect high-occupancy spaces with real, measurable proof. Learn more about Radon Exposure and Breathing Problems.

Mitigation Approaches That Work in Farm-State Conditions

Mitigation works best when it controls soil gas movement and prevents indoor buildup across all zones.

- A vent pipe and fan pull soil gas from beneath the slab and release it safely outside.

- Crews seal sump lids, cracks, and penetrations, so less radon leaks into indoor air.

- Teams place suction points strategically, so each wing maintains stable pressure control.

- A sealed vapor barrier and venting reduce radon entry from exposed ground areas.

When systems match the structure and get verified, mitigation delivers stable, measurable radon reduction long-term.

A Practical Routine for Homes, Schools, and Workplaces

A simple routine keeps radon control realistic and repeatable. Additionally, it prevents “test once and forget” habits that allow risk to return unnoticed.

- Test at purchase or occupancy changes, then retest on a consistent schedule

- Retest after renovations, HVAC changes, or major air-sealing work

- Verify mitigation performance with documented post-tests

- Maintain fans and visible indicators so the system stays checkable

- Keep records for multi-building properties, including schools and offices

This routine helps leaders compare results across seasons and prioritize the highest-occupancy spaces. Radon levels in Midwest agricultural states become manageable when teams treat testing, mitigation, and verification as a connected cycle.

Conclusion

Radon risk stays common across the Midwest, yet a disciplined plan turns uncertainty into control. Additionally, consistent testing and verified mitigation protect families, students, and employees with measurable results. If you need professional testing, mitigation, and support for residential and commercial properties in the Des Moines area, contact DSM Radon for clear guidance, accurate reports, and reliable system verification that keeps indoor air safer across every season and occupancy schedule.